Hubbard Logistics

At Hubbard, the exported day-old chicks account for 85% of the total production and amount to over 1,250 exports a year. These deliveries are shared equally between air & ground transport heading to more than 100 countries in Europe, Africa, Americas and Asia.

Hubbard's Logistics Department strives to work on 3 main areas for continuous improvement of the delivery process:

- Developing a special partnership with our carriers,

- Extending support and logistical advice for our clients,

- Encouraging and improving chick quality upon delivery - our ultimate goal.

Road transport

Hubbard's fleet uses high-performance specialist tools. Temperature, ventilation and humidity and even CO2 are controlled during transport by our highly trained and experienced drivers.

Air transport

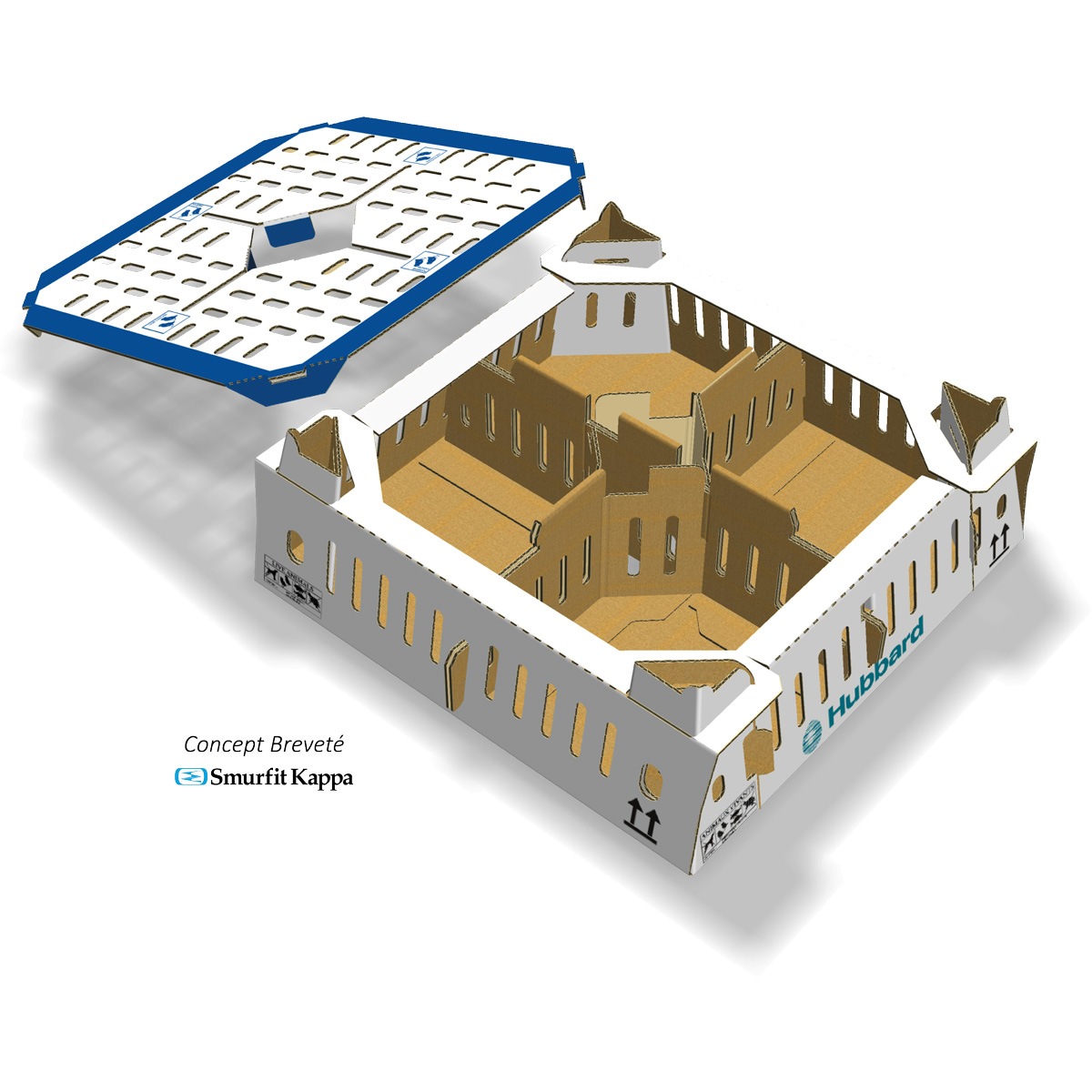

Transporting chicks by plane is a very sensitive business and so Hubbard has put its own patented containers into operation. The pallets used have a central chimney and regularly used airways, to ensure that the four compartments in the chick boxes are ideally ventilated.

Moreover, thanks to improved airport palletisation plus the implementation of a specific loading standard for planes the ventilation of our chicks is optimised for the duration of the air transport. This method has now widely been deployed by companies and many airports.

Measures taken for total management of the air logistics chain

- Use of operators exclusively specialised in transporting live animals (with physical presence at airports),

- Close partnerships with major airlines,

- Training for handling operators in both transfer and destination airports,

- Guidance and support for those receiving deliveries regarding import and customs procedures,

- Authorised Economic Operator (AEO) certification,

- "Known Consignor" certification: European accreditation awarded by the European Aviation Safety Agency following inspection of air cargo by home authorities.